From farm to consumer

Full production cycle

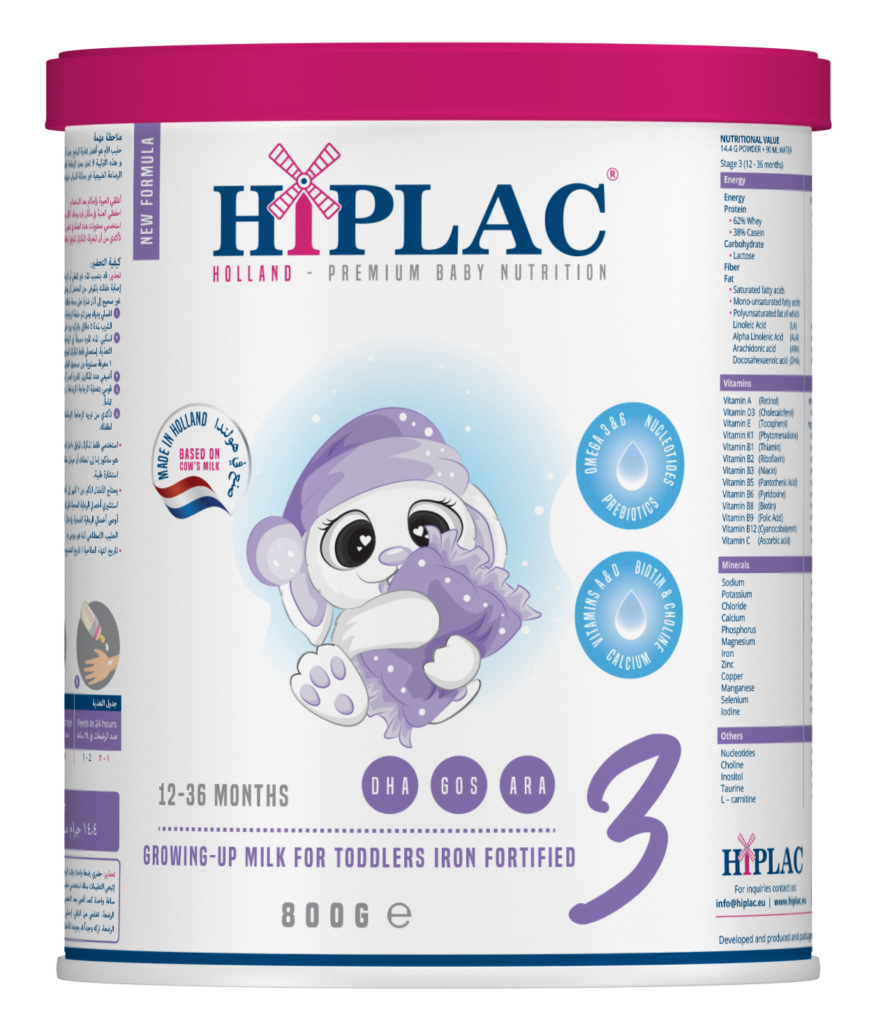

From France, the dairy heart of the world, we serve the international market with high-quality baby and infant food.

The start of our process

There is close collaboration in the French dairy chain to guarantee the quality of dairy products, through intensive checks and collaborations between farmers, dairy companies, suppliers, inspection bodies and knowledge institutes. Hiplac is proud to be part of that chain.

After receiving the milk at the factory, the versatile and critical process of converting liquid milk into formula starts.

In order to guarantee the highest quality, the entire production process takes place in a closed system. This means that contact between the product, the air and people is minimized. We maintain strict quality rules for everyone who enters our production areas.

From milk to base powder

The first step in the production process is pasteurization; the process by which the milk is heated to high temperatures, eliminating bacteria and making it safe to consume. Subsequently, the fat is removed from the milk by means of centrifuge division, resulting in skimmed milk. The skimmed milk then undergoes the process of vacuum evaporation, in which a large part of the water in the milk is removed. The thickened skimmed milk is mixed with key ingredients. Together, these ingredients form the basis for our infant nutrition products. In the drying tower, the wet mixture is then converted into high-quality base powder

From base powder to infant food